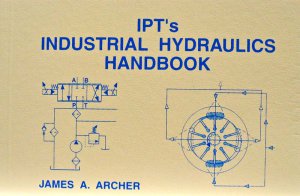

IPT’s Industrial Hydraulics Handbook

Publication Date: 2001

Book Size:5.75" x 3.75" x 0.875"

Pages; 490

Edition: 1st

Cover: Soft Bound

Author: Archer

IPT's Hydraulics Handbook and Training Manual

The Fundamentals of Hydraulic Principles

IPT’s Hydraulics Handbook and Training Manual include all the fundamental construction and operating principles for most hydraulic components. In the classroom or on the jobsite, millwrights, industrial mechanics, mechanical trade workers, equipment operators, plant operators and technicians find our Hydraulics publications essential tools of the trade.

The Most Comprehensive Hydraulics Resource Available

In addition to comprehensive information about hydraulic principles, these valuable resources include troubleshooting sections, conversion tables, hydraulic formulae, pipe and tubing charts, threading information, and ISO based graphic symbols. IPT’s Hydraulics Handbook and Training Manual...buy it today; use it every day!

-

Shipping info

We ship to most countries of the world with the exclusion of Portugal, Niger, and Nigeria.

-

Payment methods

-

Return Policy

Take a look at our return policy for full details.

Table of Contents:

SECTION ONE— HYDRAULIC PRINCIPLES

Force

Area

Pressure

Pressure Definition

Head Pressure

Gage & Absolute Pressure

Pressure Units

Force-Area-Pressure

Pascal's Law

Force Multiplication

Pressure Intensification

Creating Pressure

Pressure to Move Load

Flow of Liquids

Flow through Orifice

Flow Rate Measurement

Volume Measurement

Actuator (cylinder) Speed

Flow Velocity Measurement

Changing Pipe Size

Laminar & Turbulent Flow

Flow Intensification

Parallel Flow Path

Series Flow Path

Bernoulli’s Equation

Energy, Torque, Power

Energy

Torque

Power

Heat Generation

Heat Dissipation

Graphical Symbols

SECTION TWO — FLUIDS

Fluid Functions

Fluid Properties

Viscosity

Measuring Viscosity

Viscosity Index

Choosing Correct Viscosity

Pour Point/Cloud Point

Flash Point/Fire Point

Oxidation Resistance

Corrosion Prevention

Demulsibility

Fluid Types

Petroleum Based

Biodegradable Fluids

Fluid Contamination

Contamination Sources

Measuring Contamination

Specifying Level

Allowable Level

Filters

Filtration Efficiency

Filtering Media

Handling Fluids

Sampling and Testing

SECTION THREE —PIPING

Piping

Sizes and Schedules

Piping Pressure

Pipe Fittings

Pipe Threads

Pipe Threading

Tubing

Tubing Materials

Tubing Fittings

Flareless Fittings

Welded Fittings

Tubing Pressure

Tubing Installation

Flexible Hose

Flexible Hose Sizes

Flexible Hose Pressure

Flexible Hose Installation

Flexible Hose Assemblies

Connecting Components

NPT Connections

SAE Straight Thread

O-Ring Flange

Other Threads

SECTION FOUR —ACCESSORIES

Reservoirs

Function, Size, Shape

Connections, Fittings

Reservoir Features

Accumulators

Weight Loaded

Spring Loaded

Gas Loaded

Piston Type

Bladder Type

Intensifiers

Pressure Gages

Pressure Switches

Heat Exchangers

Shell and Tube

Radiating Type

Immersion Type

SECTION FIVE — PUMPS

Pumping Principles

Displacement

Fixed and Variable

Pump Volumetric Efficiency

Mechanical Efficiency

Overall Efficiency

Pump Pressure Rating

Gear Type Pumps

External Gear Pump

Internal Gear Pump

Sliding Vane Pump

Fixed Displacement Vane

Variable Displacement Vane

Piston Type Pumps

In-Line Axial Piston

Fixed In-Line Axial

Variable In-Line Axial

Bent Axis Axial

Radial Piston Pump

Radial-Rotating Block

Radial-Rotating Cam

SECTION SIX — ACTUATORS

Actuator Function

Linear Actuators (cylinders)

Cylinder Rating

Single Acting Cylinder

Double Acting Cylinder

Telescoping Cylinder

Tandem Cylinder

Duplex Cylinder

Cylinder Cushions

Stop Tube

Rod Scraper

Dynamic Cylinder Seals

Piston Rod Bushing

Cylinder Mounting

Cylinder Sealing Problems

Piston Rod Seal Leaks

Piston to Cylinder Leaks

Piston Drift

Pressure Intensification

Piston Speed Decrease

Piston Speed Increase

Checking for Leaks

Rotary Actuators

Motor Performance Rating

Displacement

Flow and Speed

Torque

Pressure

Gear Motors

External Gear Motor

Internal Gear Motor

Direct Gerotor Motor

Orbiting Gerotor Motor

Vane Motors

In Line Axial Piston Motor

Bent Axis Axial Piston Motor

Radial Piston Motor

Rotating Cylinder Block

Stationary Cylinder Block

Direction of Rotation

SECTION SEVEN— BASIC CONTROL VALVES

Pressure Control

Relief Valves

Direct Acting Relief

Pilot Operated Relief

Relief Valve Venting

Unloading Valves

Two Pump Unloading

Accumulator Charging

Sequence Valves

Counterbalance Valves

Overcenter Valves

Brake Valves

Pressure Reducing Valves

Direction Control Valves

Check Valves

Simple Check Valve

Restriction Check Valve

Pilot-to-Open Check Valve

Pilot-to-Close Check Valve Sliding Spool Valves

Pressure Compensated Control

Bypass Type Control

Temperature Control

Sharp Edged Orifice

Metallic Rod

Actuator Speed Control

Meter-in (Restrictor)

Meter-in (Bypass)

Meter-out Circuit

Bleed-off Circuit

SECTION EIGHT— CARTRIDGE VALVES

Introduction

Cartridge Valve Sizes

Slip-in Cartridge Valves

Basic Operation

Balanced Poppet

Area Ratios

Slip-in Valve Use

Check Valve

Relief Valve

Pressure Reducing

Non-Compensated Control

By-Pass Flow Control

Restrictor Flow Control

Screw-in Cartridge Valves

Two-Way Control

Pilot Operated Relief

Direct Acting Reducing

Pressure Compensated By-Pass

Pressure Compensated Restrictor

SECTION NINE — PROPORTIONAL AND SERVO VALVES

Introduction

Closed Loop System

Open Loop System

Proportional Valves

Force Controlled Solenoids

Stroke Controlled Solenoids

Proportional Pressure Control

Pressure Reducing

Proportional Directional Control

Proportional Direction Spools

Proportional Flow Control

Servo Valves

Mechanical Servo

Electro-Hydraulic Servo

Pilot Operated Servo

Flapper Nozzle Servo

Jet Pipe Servo

SECTION TEN—TROUBLESHOOTING

Introduction

General Knowledge

Symbols and Schematics

Component Function

Component Identification

Electrical Circuit Analysis Safety

Shut Down Procedure

Dismantling Equipment

Checking the System

Checking Pressure

Checking Flow

Checking Fluid

Systematic Troubleshooting

Troubleshooting Tables

No Movement

Speed Too High/Slow

Movement Erratic

Force/Torque Too High/Low

Incorrect Pressure

Incorrect Flow

Excessive Heat

Excessive Noise

Cavitation

Actuator Wear

Hydraulic Motors

Hydraulic Cylinder Leakage

SECTION ELEVEN— TABLES AND CONVERSIONS

Metric SI Conversions

Inch — Millimetre Equivalents

Metric SI Prefixes

Equivalent Tables

Twist Drill Sizes

Tap Drill Sizes

Steel Pipe Dimensions

Pipe Thread Dimensions

Pipe Thread Allowance

Pipe Stress Values

Pipe Pressure Ratings

Pipe Flow Rates

Pipe Thread Comparisons

Tube Wall Thickness

Tube Pressure Rating

Fluid Velocities

Fluid Viscosity

Viscosity Conversion

Metal Properties

Useful Formulae

Fluid Power Formulae

SECTION TWELVE — ISO SYMBOLS

Basic Symbols

Pumps/Compressors/Motors

Pump/Motor Units

Telescoping Cylinders

Directional Control Valves

Pressure Controlled Valves

Flow Controlled Valves

Energy Sources/Connections

Reservoirs

Miscellaneous Apparatus

Control Mechanisms

Supplementary Equipment

-

ManufacturerIPT Publishing & Training LTD.

-

Publication Date2001

-

Book Size5.75" x 3.75" x 0.875"

-

Pages490

-

Edition1st

-

CoverPerfect Soft Bound

-

AuthorJames Archer

-

ISBN 100920855385

-

ISBN 139780920855386

Shipping Methods

Most of our orders are shipped in the way that is most time efficient and cost effective. In example, if you have a small order that is going to California it will be shipped by USPS Priority, as it is the most time efficient and cost effective. However, since we are in North Carolina, a small order may be sent by UPS Ground to some parts of Virginia, North Carolina, and South Carolina since it will arrive next day. If you are needing a package shipped by a specific carrier please let us know in the "Customer Notes" during the Checkout process. We are not held responsible for packages that are not delivered to you for lack of information. All international packages will be shipped by USPS Priority Express International unless otherwise chosen during the Checkout process.

Our shipping hours are from 9:00 a.m. to 2:30 p.m. Eastern Standard Time. All USPS Priority orders need to be in before 12 p.m. EST to guarantee same day shipping. Any orders placed after 2:30 p.m. EST will be processed and shipped on the next business day. In example, orders that are placed Wednesday evening with UPS 2nd Day Shipping will be shipped out Thursday afternoon and will arrive the following Monday.

Although we will be offering UPS Next Day or UPS 2nd Day, if your package does not get there on time, you will not be refunded for the shipping costs. We cannot control how UPS or USPS operates.

Also, we are limiting our international shipping to countries that have opened their borders to trade with the US. If you do not see your country listed during Checkout, please email us. After placing your order, you will receive an email confirming you understand that there will be delays with shipping out of the US. If you do not respond after a second email notification, your order will be cancelled.

International orders will be shipped once we have verified that we have all items ordered in stock. If an item is on backorder from the manufacturer we will notify you immediately. We will not do partial shipments to anywhere outside of the US. Customs Fees and Import Taxes are not part of Shipping Costs. These duties/fees are the buyer's responsibility. We will email you immediately upon receipt of an international order to confirm your understanding of this. If a package is refused due to Customs Fees or Import Taxes and returned to us, you will be refunded for the price of the products only. We request that you contact your local custom's office to find out more information about these fees and taxes before ordering from us.

Due to the nature of some of our items (i.e. size vs weight ratio) there will be added freight to certain items. Please look over your items carefully and if you have any questions contact us.

We accept the following payment methods:

If you are a business that is already established with us for Net 30 Terms, then you are more than welcome to place an order by Purchase Order and we will be glad to fulfill it for you.

Our Return Policy

If you need to return an item, e-mail us at info@pipefitter.com or call us at 910-592-1310 within 30 days of receipt for instructions. You will receive further instructions with a Return Authorization number. The Return Authorization number MUST be on the package. Any returns requested after 30 Days will be issued a 20% Restocking Fee.

Freight charges for returns/exchanges will be the responsibility of the customer. Pipefitter.com claims no responsibility for missing shipments.

All returns must be in resalable condition, and containing all the original contents.

Merchandise that has been used or show any signs of abuse cannot be returned for refund or exchange. You may be under warranty and must work with the manufacturer to resolve the issue. We will pay freight charges for the return of defective items or if we made a mistake on your original order. Any packages that are returned to us for "Incomplete Address", "Insufficient Address", or "Address - Not Known", will be held at our facility. The customer will be responsible for the second Shipping Cost to the full amount or if requested refunded for the products only.

Returned Merchandise Credits

Credit will be evaluated for each returned item individually. We will refund item costs only. Once an item is received you will be contacted so that we may process your return.

Reasons for Return

Exchange or Credit

All returns will be inspected upon receipt. Upon approval of receipt you will either be credited the monetary value or the monetary value will be put towards an exchange. You will either be credited or charged the remainder of the new order.

If you received your item as a gift, you will need to provide your own form of payment if necessary.

Functional or Visual Defects

We inspect all merchandise before we ship it. In the event that your merchandise is defective, it can be handled in one of the following ways:

“Out of the box” visual defects must be reported within 30 days of receipt.

Functional defects must be reported to the manufacturer. Here’s a list of the manufacturer’s information.

Refunds

Upon an approved receipt you will be contacted for the original payment method of your order. Eligible refunds will be credited to that method of payment. If that payment method declines you will be notified of the situation and another payment method will need to be provided.